What is yarn?

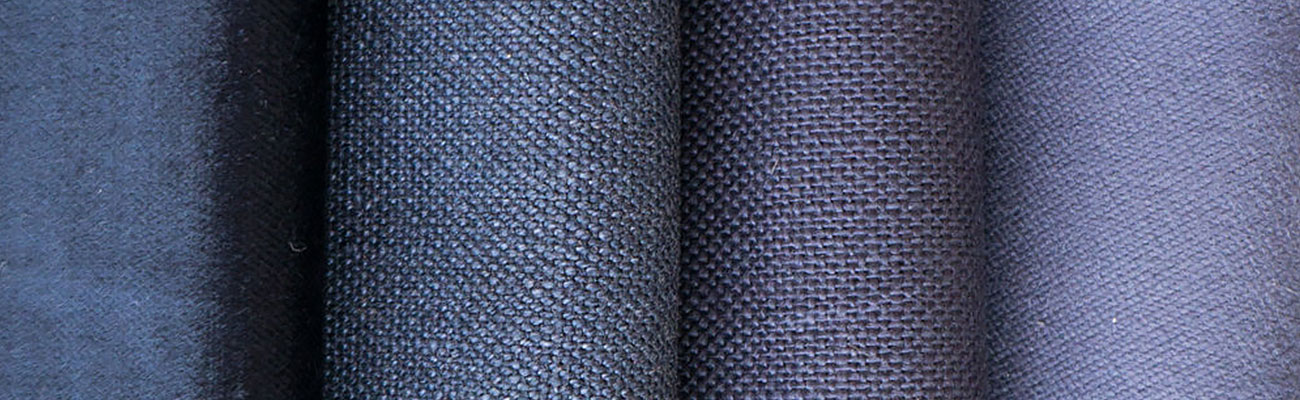

Consider a piece of cloth you have in your hand. This cloth is made of two strings of yarn, bundles along the length (warp) and bundles along the width (weft) of the warp and woven. A more precise look at the yarns show that each yarn is made up of a number of very thin strands (fibers) twisted together. To put it simply, thin, long, flexible fibers used in yarn are called fibers. These thin strands (fibers) similar to infants’ hairs are soft, fine, and pliable; therefore, they can be placed in a bundle along each other to make a very long cylinder combined of air and fiber that is called yarn. Yarn has weavabililty (converted to fabric) and finally becomes garment. These fine fibers have very diverse physical and mechanical properties; some like cotton are rooted in nature, and others such as polyester, viscose, and nylon are synthetic and man-made. Each of these fibers is distinct from each other and has different characteristics that meet some of the human needs. However, what determines the use and survival of a fiber in the textile industry is to some properties that satisfy the following four criteria.

- Is it easy to make yarn out of that?

- Is that feasible for mass production?

- Does it have an effective role in reducing final cost of the finished product?

- Does it satisfy the consumer’s desired properties?

Nowadays, answering to the last question, namely, the provision of favorable properties for the consumer, plays a key and the most important role in the survival of a fiber.